Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

Knife Making Experience (2 Day Course)

Braydeston Knives is very pleased to finally give you the opportunity to create your very own kitchen knife! Over the course of a weekend you'll learn about the science and processes of knife making, getting to take a piece of steel from a blank canvas and turn it into your one of a kind knife to take home!

How it works and what you'll be making

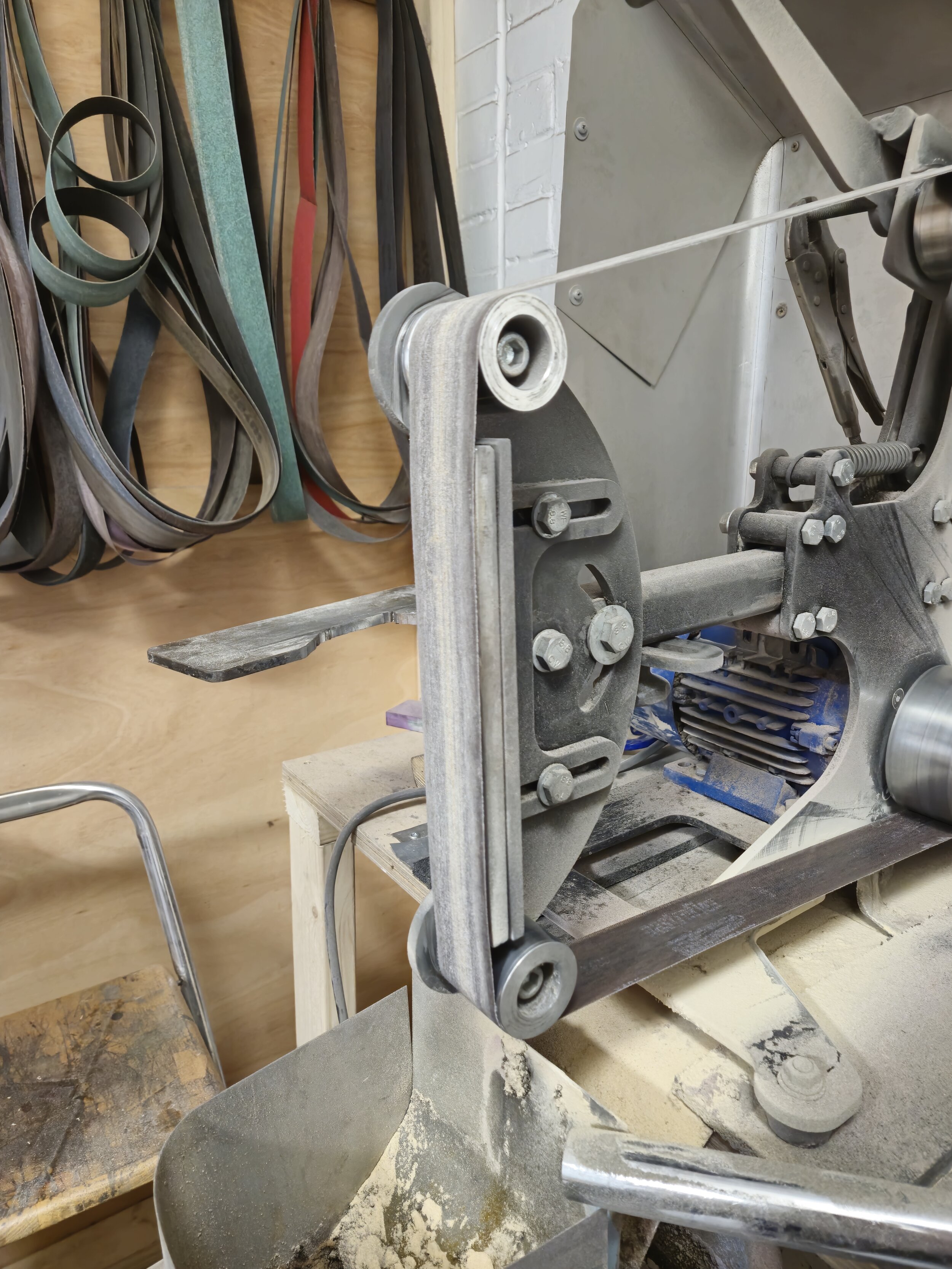

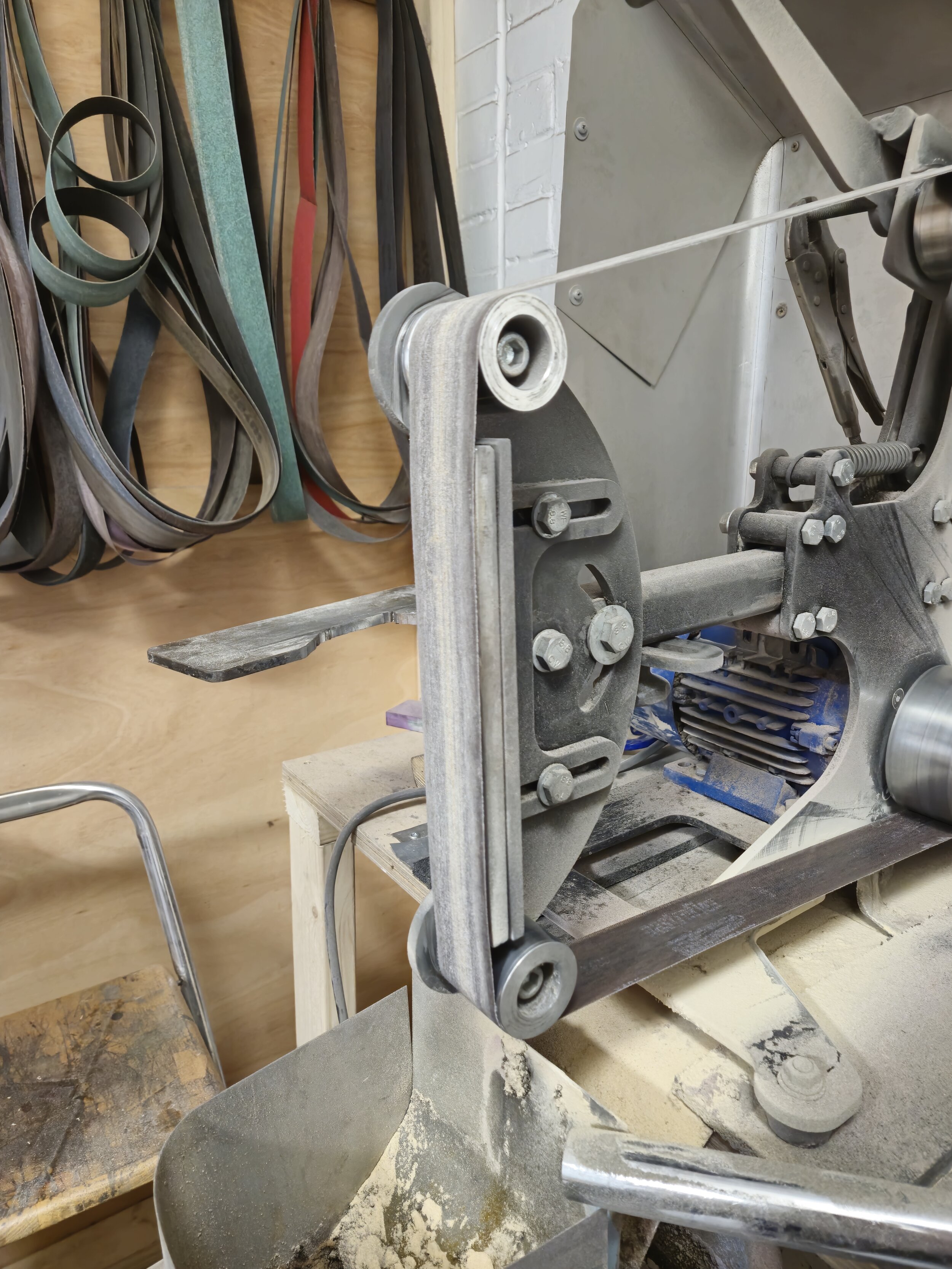

At Braydeston knives we make Stainless kitchen knives and the course will be no different! Over the course of the weekend we'll guide you through each process and get hands-on experience on every piece of machinery needed to create your knife. This includes:

Cutting and profiling raw stainless steel

Cold hammering

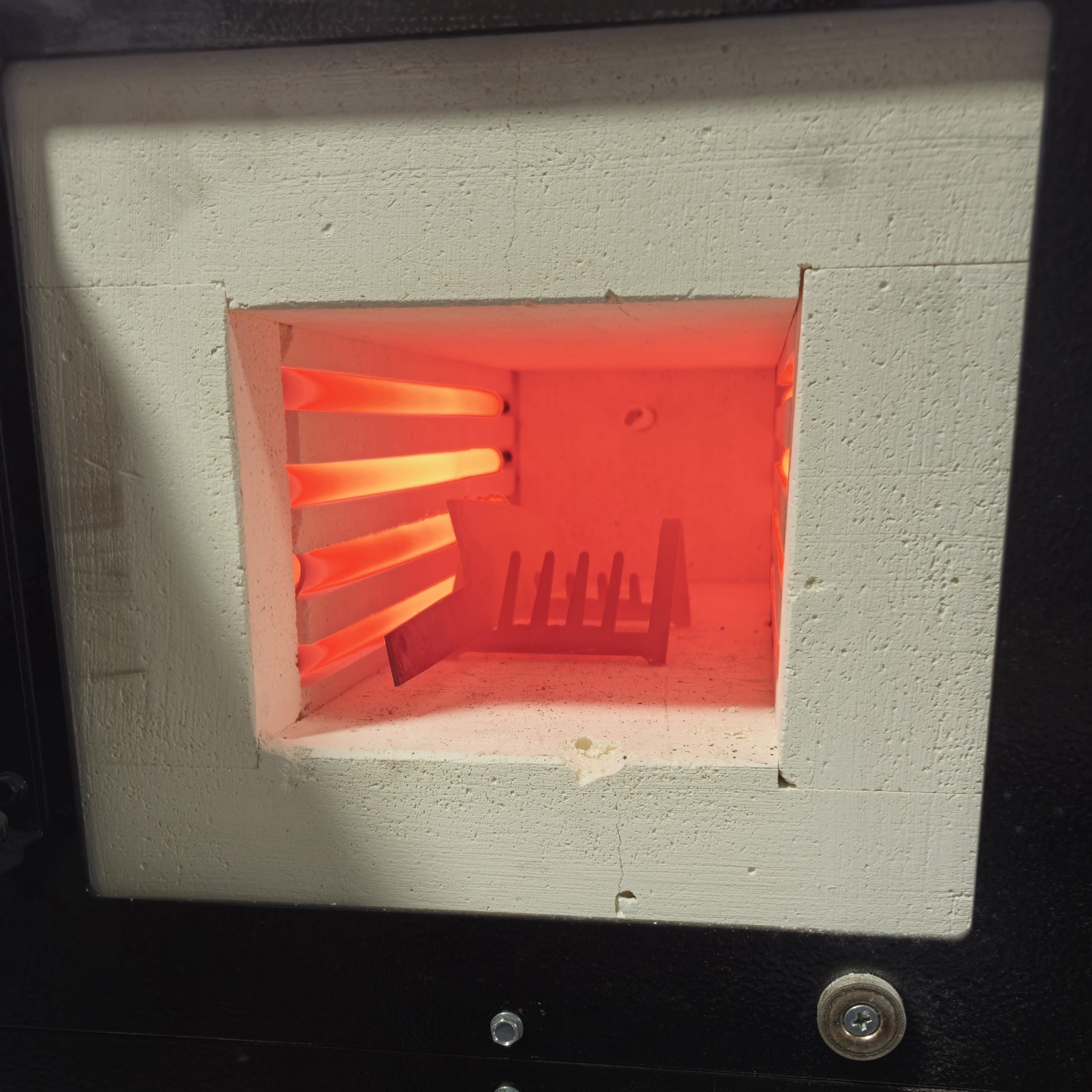

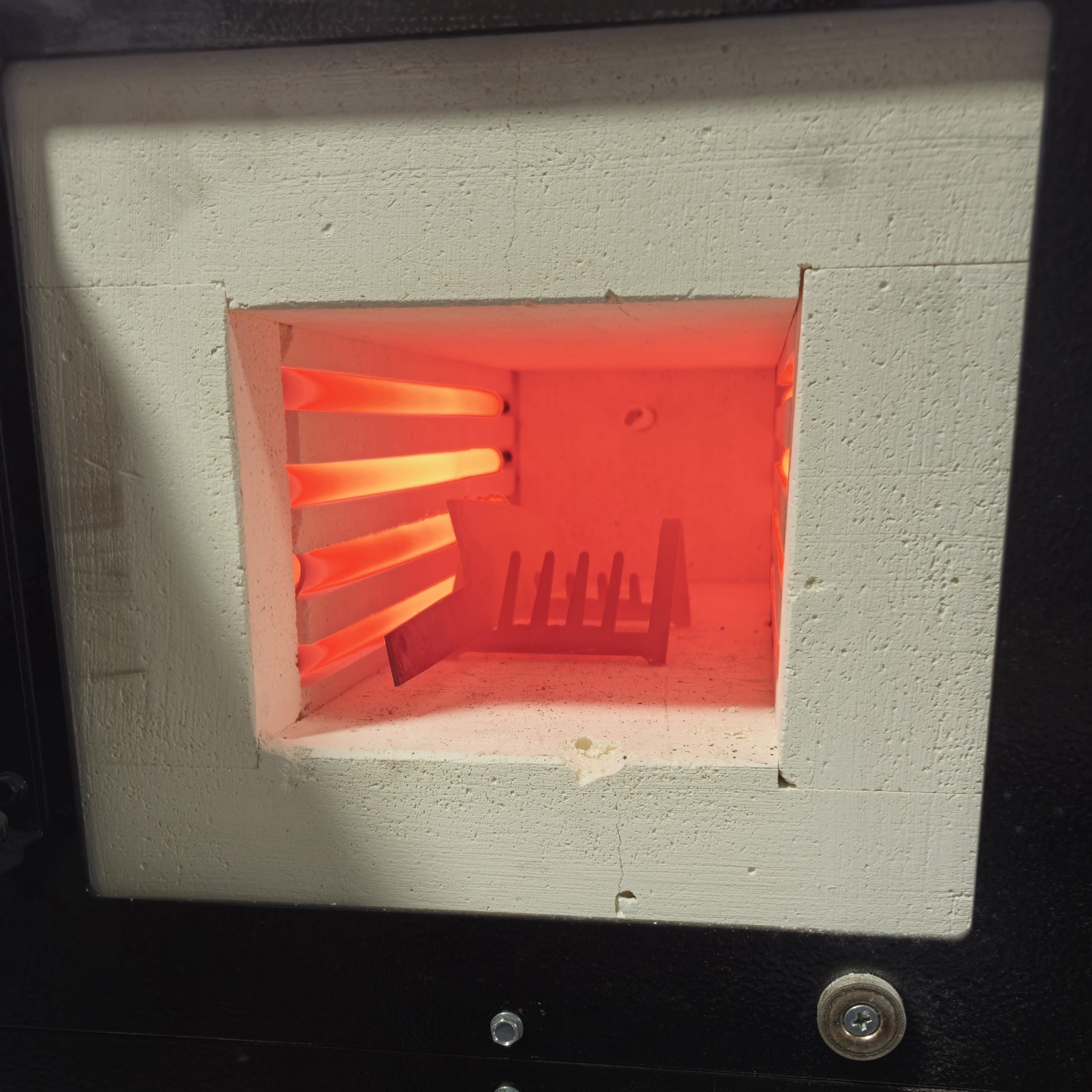

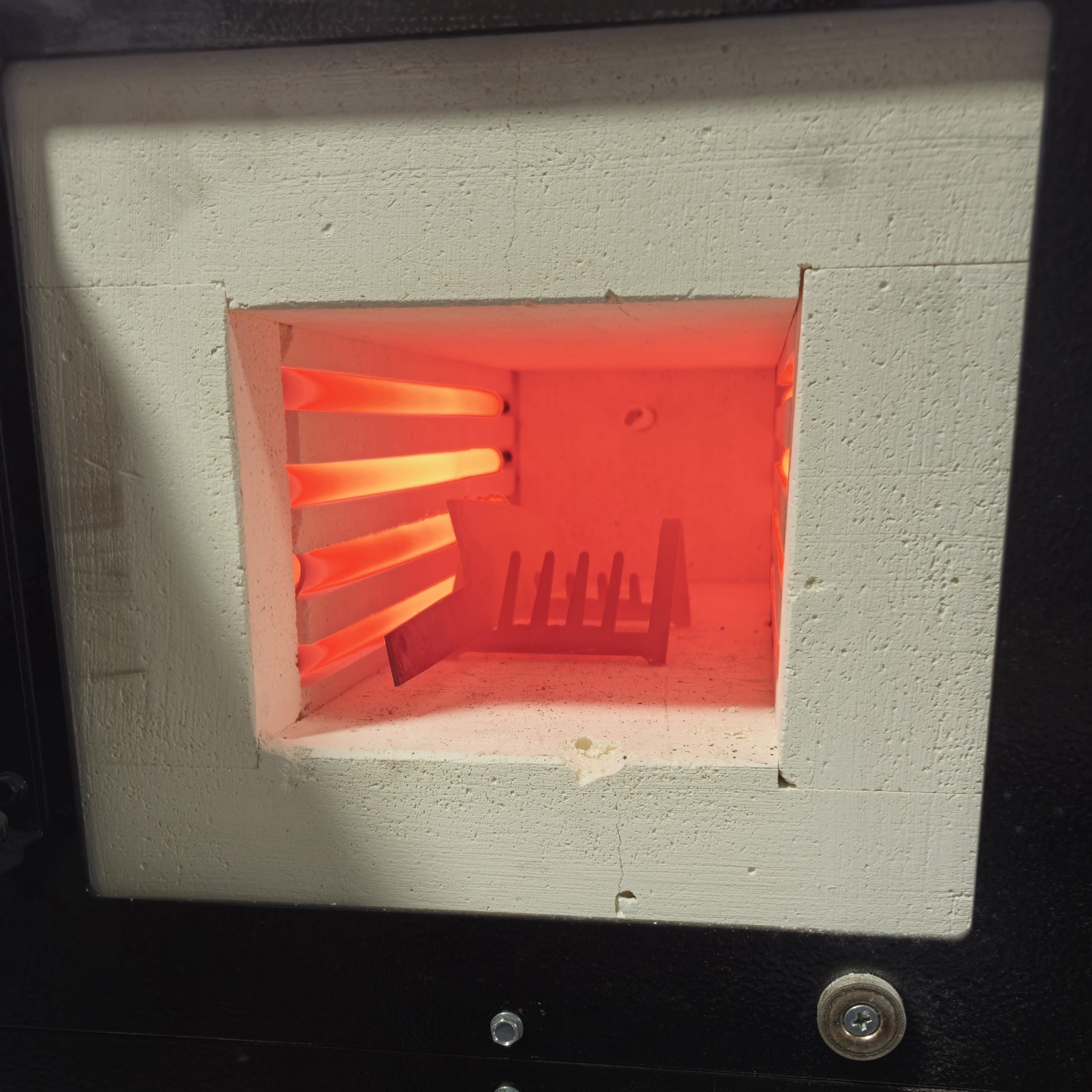

Heat treatment in our digitally controlled kiln

Grinding and bevelling for the cutting edge

Creating and shaping your handle

Personalising with our laser etching machine

Day 1 - 9:00am - 5PM Will focus on the metal work in the morning and while your knife tempers in the oven we will begin work on your handles in the afternoon.

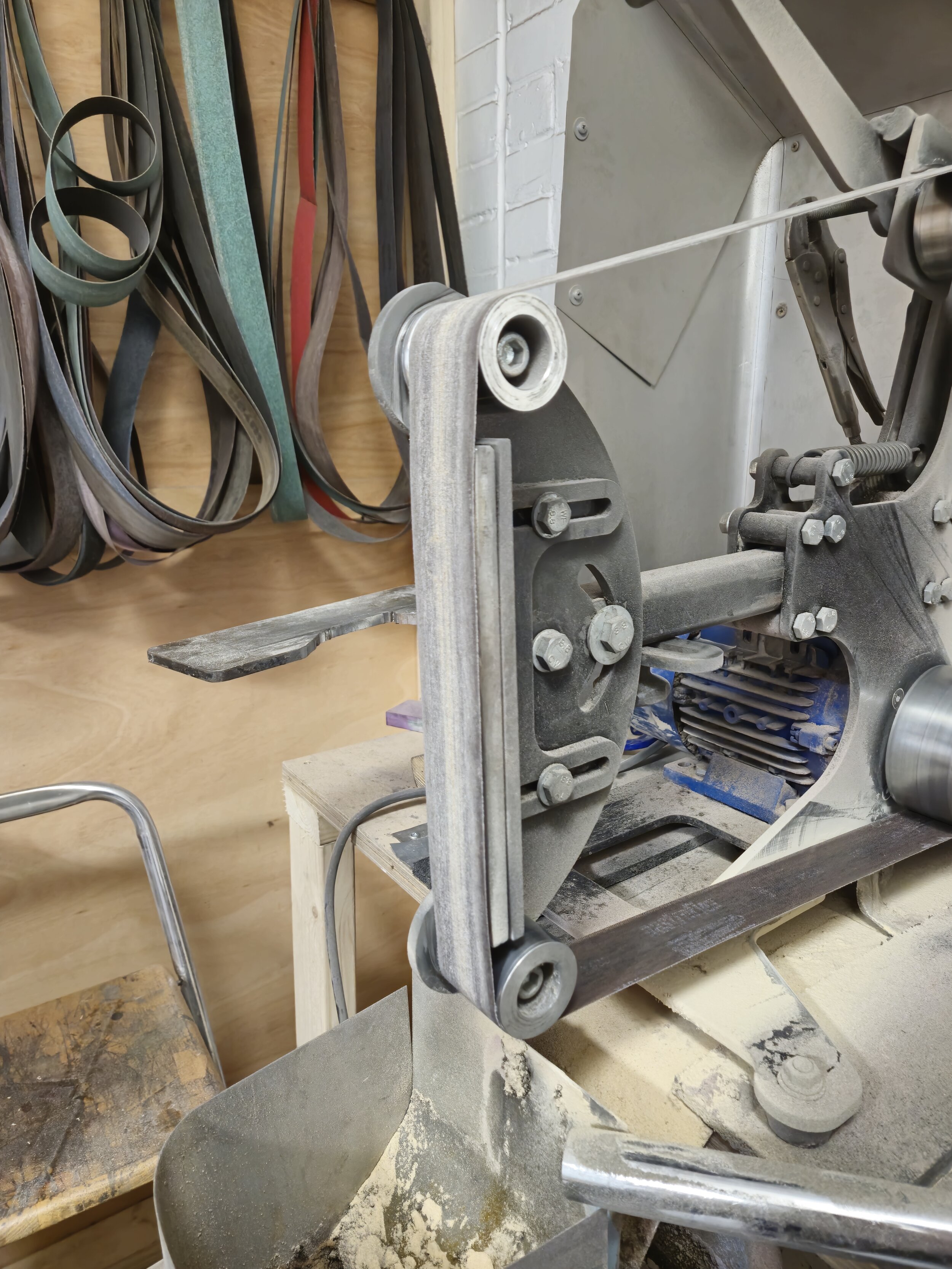

Day 2 - 10am - 5PM Sunday morning we’ll bevel your hardened knives on the 2x72 inch grinders to a final finish ready to set into the handle towards the end of the day.

What you need to bring and what we provide.

Safety Glasses and Masks will be provided. Rubberised DIY type gloves are encouraged but not provided. it is also essential to wear clothes you don't mind getting dirty!

Tea and Coffee will be provided however lunch will not however there is the wonderful bread source close by as well as Greggs and other options to keep you fuelled throughout the day.

Where to go

Braydeston Knives, 10 Derby Street, Norwich, NR2 4PU

The Workshop is very easy to find just off Heigham Street opposite the Skoda Showroom amongst a group of industrial units on the right as you enter Derby Street.

Braydeston Knives is very pleased to finally give you the opportunity to create your very own kitchen knife! Over the course of a weekend you'll learn about the science and processes of knife making, getting to take a piece of steel from a blank canvas and turn it into your one of a kind knife to take home!

How it works and what you'll be making

At Braydeston knives we make Stainless kitchen knives and the course will be no different! Over the course of the weekend we'll guide you through each process and get hands-on experience on every piece of machinery needed to create your knife. This includes:

Cutting and profiling raw stainless steel

Cold hammering

Heat treatment in our digitally controlled kiln

Grinding and bevelling for the cutting edge

Creating and shaping your handle

Personalising with our laser etching machine

Day 1 - 9:00am - 5PM Will focus on the metal work in the morning and while your knife tempers in the oven we will begin work on your handles in the afternoon.

Day 2 - 10am - 5PM Sunday morning we’ll bevel your hardened knives on the 2x72 inch grinders to a final finish ready to set into the handle towards the end of the day.

What you need to bring and what we provide.

Safety Glasses and Masks will be provided. Rubberised DIY type gloves are encouraged but not provided. it is also essential to wear clothes you don't mind getting dirty!

Tea and Coffee will be provided however lunch will not however there is the wonderful bread source close by as well as Greggs and other options to keep you fuelled throughout the day.

Where to go

Braydeston Knives, 10 Derby Street, Norwich, NR2 4PU

The Workshop is very easy to find just off Heigham Street opposite the Skoda Showroom amongst a group of industrial units on the right as you enter Derby Street.

Braydeston Knives is very pleased to finally give you the opportunity to create your very own kitchen knife! Over the course of a weekend you'll learn about the science and processes of knife making, getting to take a piece of steel from a blank canvas and turn it into your one of a kind knife to take home!

How it works and what you'll be making

At Braydeston knives we make Stainless kitchen knives and the course will be no different! Over the course of the weekend we'll guide you through each process and get hands-on experience on every piece of machinery needed to create your knife. This includes:

Cutting and profiling raw stainless steel

Cold hammering

Heat treatment in our digitally controlled kiln

Grinding and bevelling for the cutting edge

Creating and shaping your handle

Personalising with our laser etching machine

Day 1 - 9:00am - 5PM Will focus on the metal work in the morning and while your knife tempers in the oven we will begin work on your handles in the afternoon.

Day 2 - 10am - 5PM Sunday morning we’ll bevel your hardened knives on the 2x72 inch grinders to a final finish ready to set into the handle towards the end of the day.

What you need to bring and what we provide.

Safety Glasses and Masks will be provided. Rubberised DIY type gloves are encouraged but not provided. it is also essential to wear clothes you don't mind getting dirty!

Tea and Coffee will be provided however lunch will not however there is the wonderful bread source close by as well as Greggs and other options to keep you fuelled throughout the day.

Where to go

Braydeston Knives, 10 Derby Street, Norwich, NR2 4PU

The Workshop is very easy to find just off Heigham Street opposite the Skoda Showroom amongst a group of industrial units on the right as you enter Derby Street.